一、Yarn Break Monitoring Benefits

1.Reduce patrolling Reduce labors Improve efficiency 5.Reduce fluff, Reduce yarn uneveness

2.Reduce wrapping reduce damage of parts 6.Reduce empty spindle Improve production efficiency

3.Reduce weak twist guarantee yarn strength 7.Automatically collect data,Improvemanagement

4.Reduce waste 8.Reduce suction fan energy consumption

二、Major Function

1.Weak Twist/Break/Fault Spindle Indication

Sensor LED indicating positions for spinners and mechanics to discover weak twist/break/fault

spindle straightly, reduces patrolling.

2.Roving Stop Feeding

When yarn break happens, roving stop feeding device will act immediately to reduce waste, with

simply re-feeding switch.

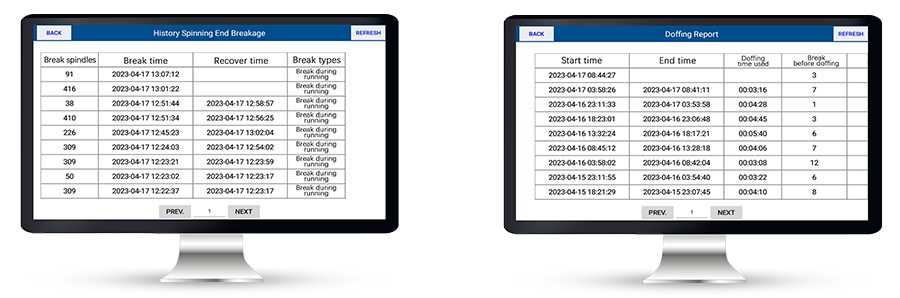

3.Break And Weak Twist Display

Scrolling displays quantity of break /weak twist/fault, convenient for remote-inspection of spinners

and mechanics.

4.Individual Machine Control Display

Android HMI displays spinning frame running performance, such as break position, output,

efficiency etc.

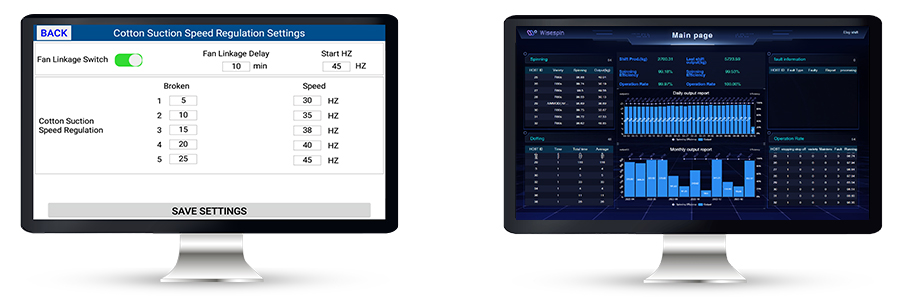

5.Data Transmission

Real time interoperability with all spinning frames will be actualized by M2M technology of inserted

IOT card.

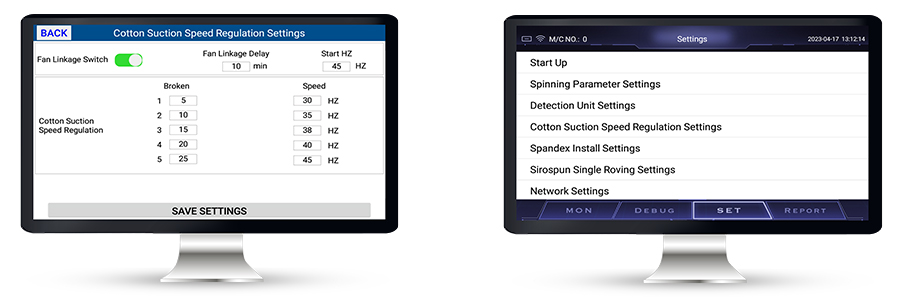

6.Optional Function

Optional function modules including suction fan inverter, obtain power-consumption data, humiture,

dust and noise etc.

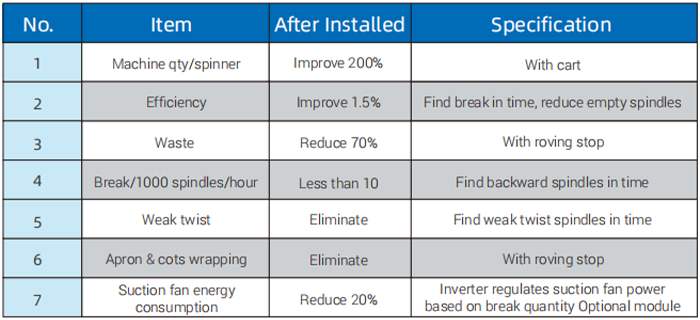

三、Effects

|